RECIPROCATING COMPRESSOR

RECIPROCATING COMPRESSOR

The compressor in which the vapour refrigerant is compressed by the reciprocating motion of the piston is called reciprocating compressors. These compressors are used for refrigerants that have comparatively low volume per kg and a large differential such as ammonia (R-717), R-12, R-22, and methyl chloride (R-40). The reciprocating compressors are available in sizes as small as 1/12 KW which are used in small refrigerators and up to about 150 KW for large capacity installations.

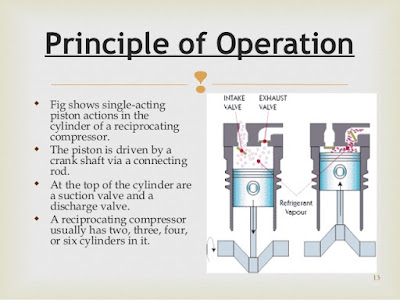

The two types of reciprocating compressors in general use are single acting and double acting horizontal compressors. The single-acting compressors usually have their cylinders arranged vertically, radially or in V or W form. The double-acting compressors usually have their cylinders arranged horizontally.

Let us consider that the piston is at the top of its stroke as shown in Fig. This is called the top dead centre position of the piston. In this position, the suction valve is held closed by the pressure in the clearance space between the top of the piston and the cylinder head. The discharge valve is also held closed because of the cylinder head pressure acting on the top of it.

When the piston moves downward (i.e. during the suction stroke), as shown in Fig, the refrigerant left in the clearance space expands. Thus the volume of the cylinder (above the piston) increases and the pressure inside the cylinder decreases. When the pressure becomes slightly less than the

Suction pressure or atmospheric pressure, the suction valve gets opened and the vapour refrigerant flows into the cylinder. This flow continues until the piston reaches the bottom of its stroke (i.e. ad bottom dead centre). At the bottom of the stroke, as shown in Fig. The suction valve closes because of the spring action. Now when the piston moves upward (i.e. during compression stroke) as shown in Fig. the volume of the cylinder decreases and the pressure inside the cylinder increases.

When the pressure inside the cylinder becomes greater than that on the top of the discharge valve, the discharge valve gets opened and the vapour refrigerant is discharged into the condenser and the cycle is repeated

It may be noted that in a single-acting reciprocating compressor, the suction, compression and discharge of refrigerant takes place in two-stroke of the piston or in one revolution of the crank

Shaft.

Notes: 1. In a double-acting reciprocating compressor, the suction and compression take place on both sides of the piston. It is thus obvious that such a compressor will supply double the volume of refrigerant than a single acting reciprocating compressor (neglecting volume of piston rode)

Notes: 2.There must be a certain distance between the top of the piston and cylinder head when the piston is on the top dead centre so that the piston does not strike the cylinder head. The distance is called clearance space and the volume there is called clearance volume. The refrigerant left in this space is at discharge pressure and its pressure must be reduced below that of Suction pressure (atmospheric pressure) before any vapour refrigerant flows into the cylinder. The clearance space should be a minimum.

The low capacity compressors are air-cooled. The cylinders of these compressors usually have fins to provide better cooling. The high capacity compressors are cooled by providing water

jackets around the cylinder.

Comments

Post a Comment